E: Richard.Goss@GossInnovations.com

CAD

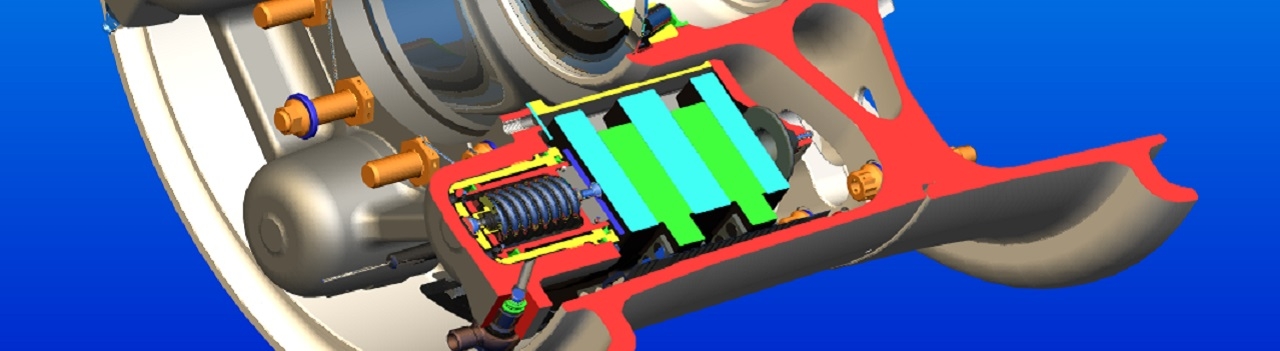

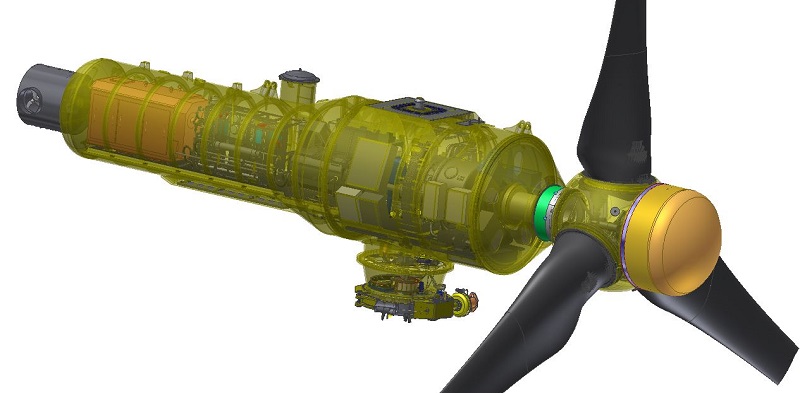

CAD drives the entire product design process from concept right through development to finished production standard drawings ready for issue. What many companies miss however are the opportunities for other downstream uses of the CAD data. Assemblies are built in the CAD system following as closely as possible the way in which they are intended to be manufactured and assembled. This allows the full use of the CAD data for producing BOMs and analysing fit, function, strength, cost, ease of assembly etc. In addition to these fairly obvious ones there are often cases where more bespoke information would be useful and we have experience in helping to extract this type of information. A good example would be a client who needed to know how the product would float in seawater. In this case a combination of Inventor and an excel spreadsheet was used to create and iterative analysis that gave this information.

We are familiar with several main stream CAD systems including NX, Solid Edge, Solid Works, Inventor & Pro Engineer. Drawings can be done to customer’s own specification using customer's drawing borders etc. It also helps to be linked directly into the customers pdm system as this allows seamless integration with the project team. We have worked in this way with several systems including Teamcentre, Inventor Vault, and Windchill.

As mentioned above we can offer customized solutions to problems via the CAD system. These can be as simple as setting up the system with company standard drawing sheets, and standard information required in a BOM, but can also include more complicated procedures relying on macros and visual basic routines. Using these techniques most CAD systems can be made to exchange information with excel spreadsheets. This can lead to some very useful downstream information being automatically generated from the CAD data.

These are the first steps towards “knowledge based engineering” which aims to capture as much as possible of a company's expertise within it’s CAD system so that all staff within the company can have effective access to it. In many companies a lot can be done to improve CAD use without having to spend more on the CAD system itself.