E: Richard.Goss@GossInnovations.com

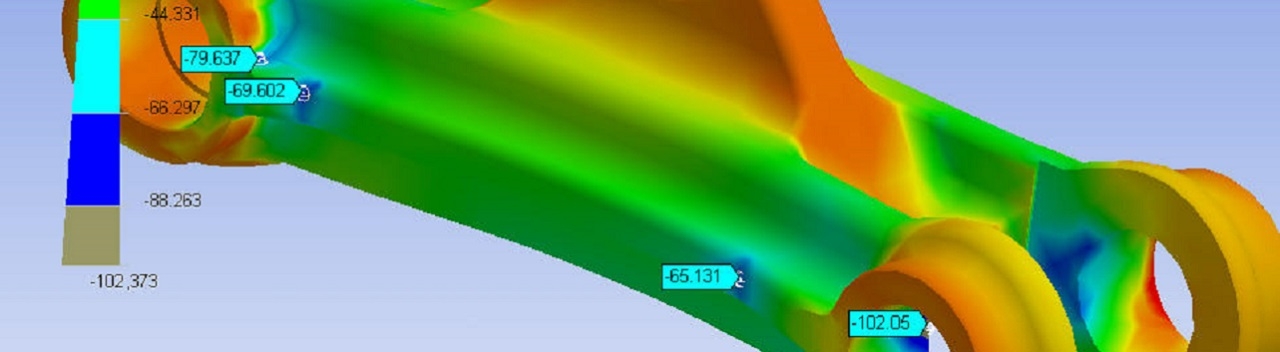

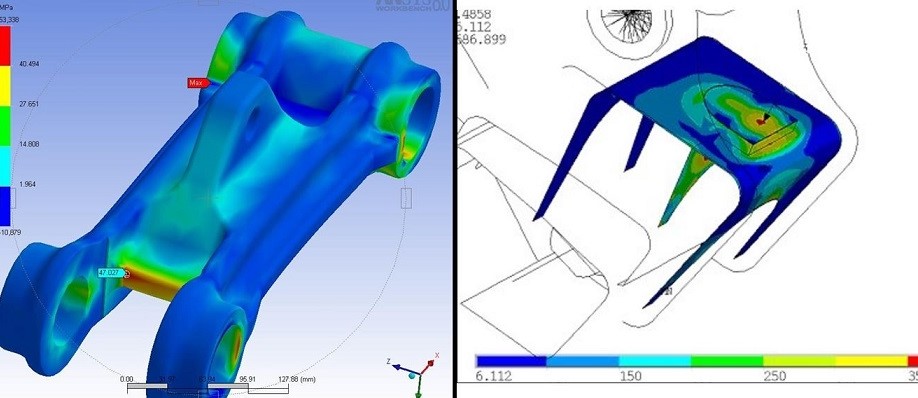

Analysis/CAE

Finite element analysis is a powerful design tool. Models are built directly from CAD data and analysed to provide estimations of stress strain and deflection under various kinds of loading. Work is carried out using Inventor Nastran. These results can be interpreted to give fatigue life predictions of both components and assemblies. We have a lot of experience using these analysis techniques for design optimisation of highly stressed welded assemblies, leading to cost effective, structurally efficient products.

Kinematic analysis is used for studying mechanisms, looking at the movement of each part with particular attention to interferences and loads generated for all critical positions and load cases. This is done with a combination of spreadsheets, hand calcs and Inventor Dynamic Simulation. Thermal analysis, harmonic analysis, acoustic analysis, and computational fluid dynamics, are all further techniques that are available to our clients.